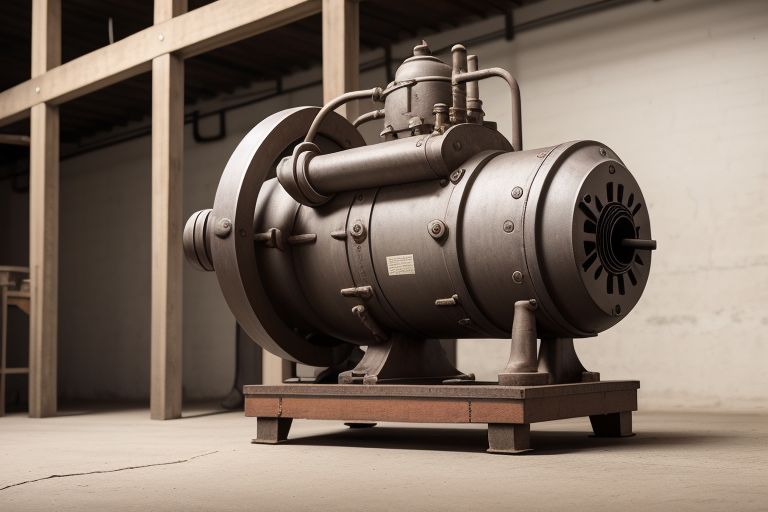

Hydraulic systems are the backbone of many industrial operations, and the quality of lubricants used directly affects performance and equipment lifespan. In this article, we explore how ferrovic.com leads the way as a trusted industrial hydraulic lubricant oil manufacturer and supplier in KL and Selangor, delivering reliable solutions for a wide range of machinery and sectors.

The Role of High-Quality Hydraulic Oils in Industry

Hydraulic oils serve as the lifeblood of heavy machinery, enabling smooth operation, efficient energy transfer, and extended component life. Choosing the right lubricant is crucial, especially in sectors such as manufacturing, construction, logistics, and automation.

Key benefits of high-quality hydraulic oils include:

- Thermal Stability: Ensures consistent performance under high temperatures.

- Oxidation Resistance: Prolongs oil life and reduces maintenance needs.

- Anti-wear Protection: Safeguards pumps, valves, and motors from damage.

- Contamination Control: Minimizes system failures due to particulates and moisture.

Ferrovic.com formulates hydraulic lubricants tailored for Malaysian industries, ensuring optimal efficiency even in tropical environments where heat and humidity are factors to consider.

Why Ferrovic.com is a Preferred Supplier in KL & Selangor

As a leading name in industrial hydraulic lubricant manufacturing and supply, ferrovic.com brings years of technical expertise and product innovation to clients across Kuala Lumpur and Selangor.

Highlights of their services include:

- Custom-formulated hydraulic oils based on specific application requirements

- Local warehousing and fast delivery to industrial zones in the Klang Valley

- Technical support and oil analysis services for proactive maintenance

- Availability of food-grade, biodegradable, and heavy-duty variants

Whether you’re operating CNC machines, injection molding systems, or automated material handling units, Ferrovic provides lubrication solutions that enhance reliability and reduce downtime.

Conclusion:

For businesses seeking durable, high-performance hydraulic lubricants in KL and Selangor, ferrovic.com is the trusted manufacturer and supplier. Their specialized formulations and commitment to service ensure machinery stays protected, efficient, and productive in demanding industrial environments.