Description

| ITEM | CODE | DESCRIPTION | INFO | SDS | PDS |

|---|---|---|---|---|---|

| 1 | CV10 | VCI Emitter | InfoFOVAC® CV10 VCI Emitteris a unique formulation Vapor Corrosion Inhibitor Powder for dry corrosion protection of metals in recessed areas, interior cavities and voids. It is specially formulated to give superior rust and corrosion protection to the interior compartment of all types of metal. FOVAC ® CV10 has found considerable application as a corrosion inhibitor in low concentrations and is effective in protecting multi-metals from corrosion. It is non-toxic, nitrite free and does not contain chromates. | Enquire | Enquire |

| 2 | F310 | Anti Rust Liquid | InfoFOVAC® Anti Rust Liquid is a highly effective anti-rust oil that is indispensable for usage in humid tropical climate as well as for storage and transportation protection. It is an organic filming compound which prevent rust and corrosion from forming on ferrous metals during indoor and outdoor storage. FOVAC ® F310 is not subjected to rancidity caused by bacterial decomposition. It is transparent to permit visibility of work components and may be removed at later stage by petroleum solvents and suitable alkaline cleaners like our FOVAC ® F316 Solvent Degreaser and FOVAC ® F17 WS Machinery Degreaser respectively. | Enquire | Enquire |

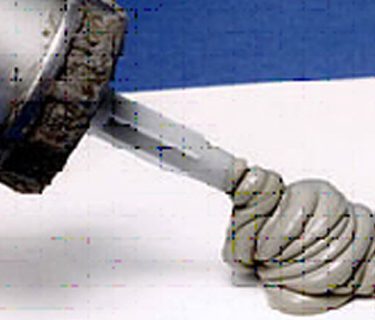

| 3 | F312S | Synthetic Rust Converter | InfoFOVAC® F312S Synthetic Rust Converter is one step application to convert rust (iron oxide) to a protective blue-black magnetite coating. This new acrylic coating prevents the metal from further corrosion and provides a base for paint to bond properly. Rust forms a major problem in the industry and the financial losses due to rust account to million of dollars. FOVAC ® F312S is the latest coating technology for preserving iron and steel surfaces from corrosion. It actually changes the rust into a tough, durable protective coating – that last from 2 to 5 times longer than ordinary paints! FOVAC ® F312S saves you money by saving you labor. Apply it directly to rusty surface no sanding, grinding, blasting, or etching required. It leaves the surface primed and ready for paint. Use it on offshore platforms, barges, ships, refineries, water treatment plants, structures, bridges, fences, pipe lines, engine parts, walk ways, ships, drums, tanks, steel, cars, trucks, and equipment – anywhere rust is a problem! This ready-to- use formula is safer to handle, non-flammable, and easy to clean up | Enquire | Enquire |

| 4 | F315 | Rust Remover (Acidic) | InfoFOVAC® F315 Rust Remover is a very versatile formulation for derusting, degreasing and phosphatizing of steel. It provides an amorphous coat of iron phosphate to inhibit rust creep and improve paint adhesion. FOVAC ® F315 is a highly concentrated well inhibited liquid, with built-in boosters, wetting agents and glycol grease removers. At use concentration, it removes thin films of oil and grease, dissolves rust and other metallic oxides, and deposits a microfilm of metal phosphate which protects the metal from further oxidation. It is an effective phosphatizing agent highly recommended for use on aluminum, all types of steel, brass and copper. It will not affect coated, painted, ceramic or wooden surfaces. FOVAC ® F315 can also be used in removing stain and rust from chrome-plated steel without damaging the surface. | Enquire | Enquire |

| 5 | F318 | Wax Based Corrosion Protection Coating | InfoFOVAC® F318 Rust Preventive Coating is a durable Rust and Corrosion Protection Compound for all types of metal surfaces. FOVAC ® F318 effectively displaces moisture from any wet surfaces to form a light colored protective coating that can last for years. | Enquire | Enquire |

| 6 | F323 | Conformal Coating | InfoFOVAC® F323 Conformal Coating is a thin polymeric film typically applied at 25-250 μm to electronic circuitry to act as protection against moisture, dust, chemicals, and temperature extremes. The coating ‘conforms’ to the contours of a printed circuit board (PCB) to protect the board’s components. When electronics must withstand harsh environments, most circuit board assembly houses coat assemblies with a layer of transparent conformal coating. In addition, Conformal coatings are being used as a mitigation to reduce the potential of tin and zinc whisker short circuit risk on electronic assemblies using lead-free finishes and solders. | Enquire | Enquire |

| 7 | F326 | CVI Corrosion Protection Coating | InfoFOVAC® CVI Corrosion Protection Coating is a specially formulated heavy duty rust preventive metal treatment coating which has very good spreadability (one liter covers up to 50 square feet). FOVAC ® CVI chemically bonds to steel to form a semi-hard, non-porous coating that won’t crack chip, or peel. It works by isolating metal from moisture. Without moisture present, steel can’t rust. FOVAC ® CVI provides a clear, tough, durable and flexible protection and waterproofing for all spare parts, moulds, machine parts, offshore equipment, motor windings, pipe threads, outdoor decorative ornaments, terminations, printed circuit boards, panels and other equipment.FOVAC ® CVI contains a blend of special state-of- the-art liquid polymers that forms a barrier coating to insure corrosion and rust prevention in very severe corrosive and marine environments. | Enquire | Enquire |

| 8 | F327 | ZRP Cold Galvanize Coating | InfoFOVAC® ZRP Cold Galvanizing Coating contains a special blend of zinc compound for use as a long term galvanic protection of all types of steel. When coated on a well prepared surface, FOVAC ® ZRP works by an electrochemical process to give excellent protection that last for years. Special polymer resins acts as a super binder that adheres to the steel surface to give it outstanding protection against cracking and peeling in hazardous environment | Enquire | Enquire |

| 9 | FAC802M | PBA 50M Corrosion Inhibitor (Water Base) | InfoFOVAC® PBA 50M Corrosion Inhibitor is another water-soluble rust prevention concentrate that is in the FOVAC range of high quality chemicals. It is commonly used for mixing into other liquid medium to enhance the corrosion resistance of the medium. FOVAC ® PBA is use to protect steel, copper, brass, aluminium, bronze and their alloys in a very economical way and it further diluted with water and highly recommended for use in hot and humid tropical climate where the chances of rust and corrosion problems are amplified and of major concern. FOVAC ® PBA has many special features and it is specified in the industry because of it’s rust prevention, non-staining and guaranteed results. | Enquire | Enquire |

| 10 | FCW151 | FSP Synthetic High Temperature Chain Lube | InfoFOVAC® is the premium corrosion inhibiting paper that provides superior corrosion protection for both ferrous and non-ferrous metals. FOVAC ® VP146 multimetal paper eliminates the need of a variety of papers for all the different types of metals and alloys you need to protect. FOVAC ® VP146 is fully recyclable/repulpable, that means it can be recycled into other types of paper products such as boxes, cardboard and other corrugated materials. Additionally, FOVAC ® VP146 is environmentally safe, non-toxic, biodegradable and doesn’t contain any nitrites, phosphates, or silicates. FOVAC ® VP146 paper is made from the highest quality neutral natural kraft paper, this eliminates package contamination found with other competing VCI/VPI papers. FOVAC ® VP146 is easy to use, just wrap your products in the paper, and fold edges together. Use adhesive tape as needed to hold paper folds in place. The VpCI coating on the paper vaporizes, reaching all metal surfaces to provide complete corrosion protection. The unique inhibiting action of FOVAC ® VP146 forms a very thin and very effective protective layer that does not alter the appearance of products or require removal before further finishing or use. Parts protected with FOVAC ® VP146 can be painted, welded, and soldered. This protective layer does not influence physical properties of most sensitive electrical components, including conductivity and resistance. | Enquire | Enquire |

Anti corrosion manufacturer supplier company in Malaysia

Industrial corrosion protection agents: extend component life

Corrosion can seriously affect your processes and products and lead to major repairs, production downtime and costs. By using a matching corrosion protection agent you provide optimal preservation to your components and achieve effective protection against damage to your business.

Lubrication and protection for your components: significant reduction of wear and decomposition processes with various materials

Tested effectiveness: numerous tests on in-house test rigs

Matching solutions: made specifically for individual requirements

High-performance product range: competence and expertise gained from more than 90 years of research and experience